As a high-energy-density energy storage device, lithium batteries have become the core components of portable electronic products, electric vehicles, and large-scale energy storage systems since their introduction in the 1970s. This article aims to comprehensively introduce the working principle, material system, manufacturing process, performance evaluation, challenges and future development trends of lithium batteries.

Lithium batteries store and release charges through the migration of lithium ions between the positive and negative electrodes. During the charging process, lithium ions are deintercalated from the positive electrode and migrate to the negative electrode through the electrolyte and embedded in it; during discharge, lithium ions migrate in the opposite direction, deintercalating from the negative electrode back to the positive electrode, while electrons flow through the external circuit to generate current. This process depends on the stability and ionic conductivity of the electrolyte, as well as the lithium insertion/deintercalation ability of the electrode material.

Common positive electrode materials include lithium cobalt oxide (LiCoO2), ternary materials (such as Li(NiCoMn)O2), lithium iron phosphate (LiFePO4), etc. Lithium cobalt oxide is widely used in consumer electronics due to its high energy density, but it is expensive and has limited resources. Ternary materials combine the advantages of nickel, cobalt, and manganese, balancing energy density and safety. Lithium iron phosphate is suitable for electric vehicles and large energy storage systems due to its good cycle stability and safety.

Graphite is currently the most commonly used negative electrode material, with good lithium insertion/extraction performance and stable electrochemical properties. However, in pursuit of higher energy density, silicon-based materials have attracted attention due to their extremely high theoretical capacity, but their volume expansion problem is still a technical problem that needs to be solved urgently.

Liquid organic electrolytes are currently the mainstream choice, but their flammability limits the safety of batteries. The development of solid electrolytes has become a hot topic of research and is expected to significantly improve the safety and cycle life of batteries.

The production process of lithium batteries includes raw material preparation, electrode preparation, cell assembly, charge and discharge testing and other links. The application of automation and precision control technology improves production efficiency and product quality. In addition, green and environmentally friendly production processes are also an important direction for the development of the industry.

The performance evaluation of batteries mainly includes energy density, power density, cycle life, safety and environmental adaptability. Energy density determines the battery’s endurance, power density is related to the battery’s rapid charging and discharging capabilities, cycle life affects the battery’s economy, safety is the basis for ensuring battery use, and environmental adaptability is related to the battery’s stability under different temperature and humidity conditions.

The development of lithium battery technology faces many challenges, including cost control, energy density improvement, safety performance enhancement, and material sustainability. Especially for electric vehicles and large-scale energy storage markets, how to reduce costs, increase energy density, and ensure safety is the key to industry development

Main application areas of lithium batteries

Lithium batteries have been widely used in many fields due to their high energy density, long cycle life, and good environmental adaptability. Here are some of the main application scenarios of lithium batteries:

1. Electric vehicle industry: Lithium batteries are the key energy source for electric vehicles (EV) and plug-in hybrid electric vehicles (PHEV), providing the necessary power and endurance

2. Consumer electronics industry: Smartphones, laptops, tablets, digital cameras, game consoles and other portable electronic devices rely heavily on lithium batteries as a power source

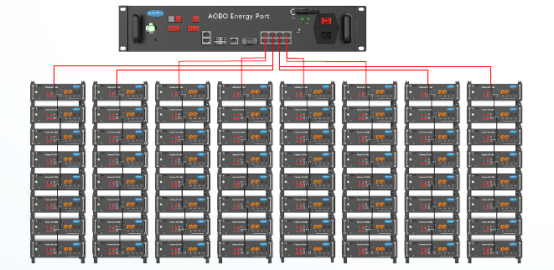

3. Energy storage industry: Lithium batteries are used in grid energy storage systems, home energy storage solutions, energy storage of renewable energy (such as solar and wind energy), and frequency modulation and backup power for the grid

4. Aerospace industry: Satellites, spacecraft, drones and other aerospace equipment use lithium batteries as a stable power source, especially in situations where long-term autonomous operation is required

5. Medical equipment industry: Portable medical devices such as pacemakers, blood glucose monitors, etc. rely on lithium batteries to provide continuous power

6. Military and security Field: Lithium batteries are used in military equipment such as unmanned reconnaissance aircraft, night vision equipment, and individual power supplies to provide reliable energy support

7. Power tools and small household appliances: Power tools, portable vacuum cleaners, electric toothbrushes and other equipment are also increasingly using lithium batteries as power

8. Electric toys and lighting equipment: Lithium batteries provide portable and long-lasting energy solutions for remote-controlled toys, aircraft models, ship models, emergency lights, lawn lights and other products

9. Beauty care and medical equipment: Electric beauty equipment, hairdressing equipment, hearing aids, electric wheelchairs and other equipment use lithium batteries to provide stable power

10. Other professional applications: Including instruments and meters, GPS positioning equipment, high-temperature power supply systems, cold-proof equipment, etc., lithium batteries also play an important role in these fields

The future development of lithium battery technology will focus on the application of new materials, the innovation of manufacturing processes, the development of intelligent management systems, and the improvement of recycling systems. Research on new battery technologies such as solid-state batteries, lithium-sulfur batteries, and lithium-air batteries will bring new growth and changes to the lithium battery industry.

As a core component of the modern energy revolution, the technological progress of lithium batteries will also promote the development of the entire new energy industry. Through continuous R&D investment and technological innovation, lithium batteries will achieve new breakthroughs in energy density, safety, cost-effectiveness, etc., and meet the growing needs of network security and environmental protection.